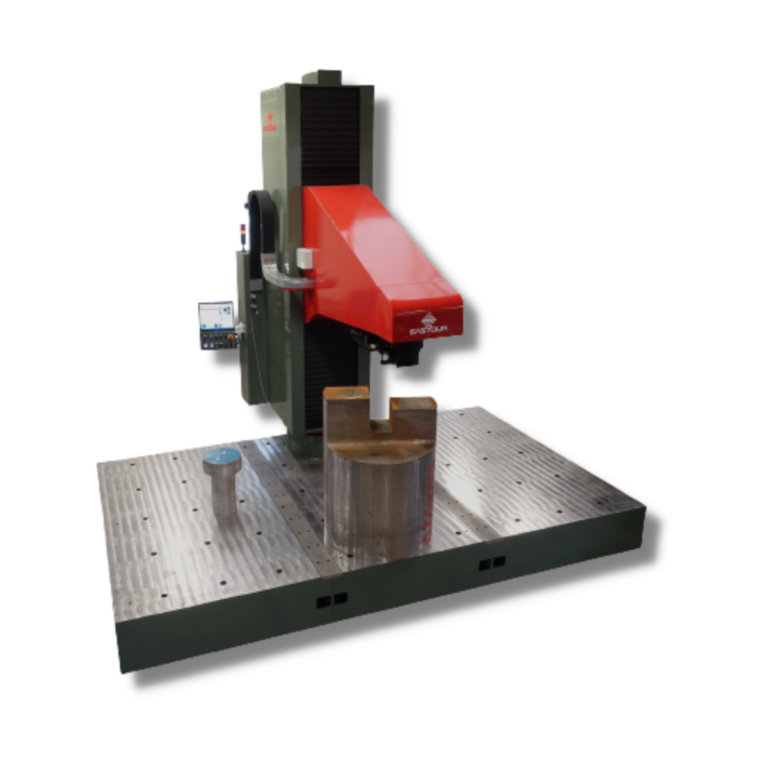

Special hardness testing machines

Hardness testing machines are used to determine the strength and character of a material. The testing process is carried out using an indenter to measure the depth indentation. At EASYDUR, metals are the main materials used in the testing phases.

SOMECO has been selling hardness testers since it was founded in 1967. For several decades, its technicians have been recognised for their skill and expertise.

EASYDUR sells all over the world and has already carried out French projects in various industries, including aeronautics, the oil industry, and metallurgy.

The technical and sales teams speak French, which is an asset when it comes to studying specifications or customising a machine to suit the customer’s application.

Whatever the type of parts you have to test, whether they are small or very large, whatever their material, there is bound to be an EASYDUR hardness testing machine to measure the hardness of your production.

Les EASYDUR hardness testers can perform all types of tests.

- BRINELL (load 187.5 to 3000 kg), (standard: EN-ISO 6506)

- ROCKWELL (load 60-100-150 kg), (standard: EN ISO 6508)

- VICKERS (loads from 1 to 50 kg), (standard: EN ISO 6507)

- UNIVERSAL (machine for 3 hardness tests)

All hardness testers have an OPC-UA (Open Connectivity, Unified Architecture) software module with an Industry 4.0 interface to management software. This provides a reliable and secure data exchange standard and facilitates networking.

EASYDUR hardness testers are designed and manufactured in Italy, north of Milan.