Metallography is a technique used to determine the structure of a metal by observing it with an optical microscope or by testing it on a durometer. This allows us to determine the nature of the structure, grain size and shape, the nature and content of inclusions, and the presence of any heat treatment.

Our range includes metallographic cut-off machines, hot and cold coating machines, and polishing machines.

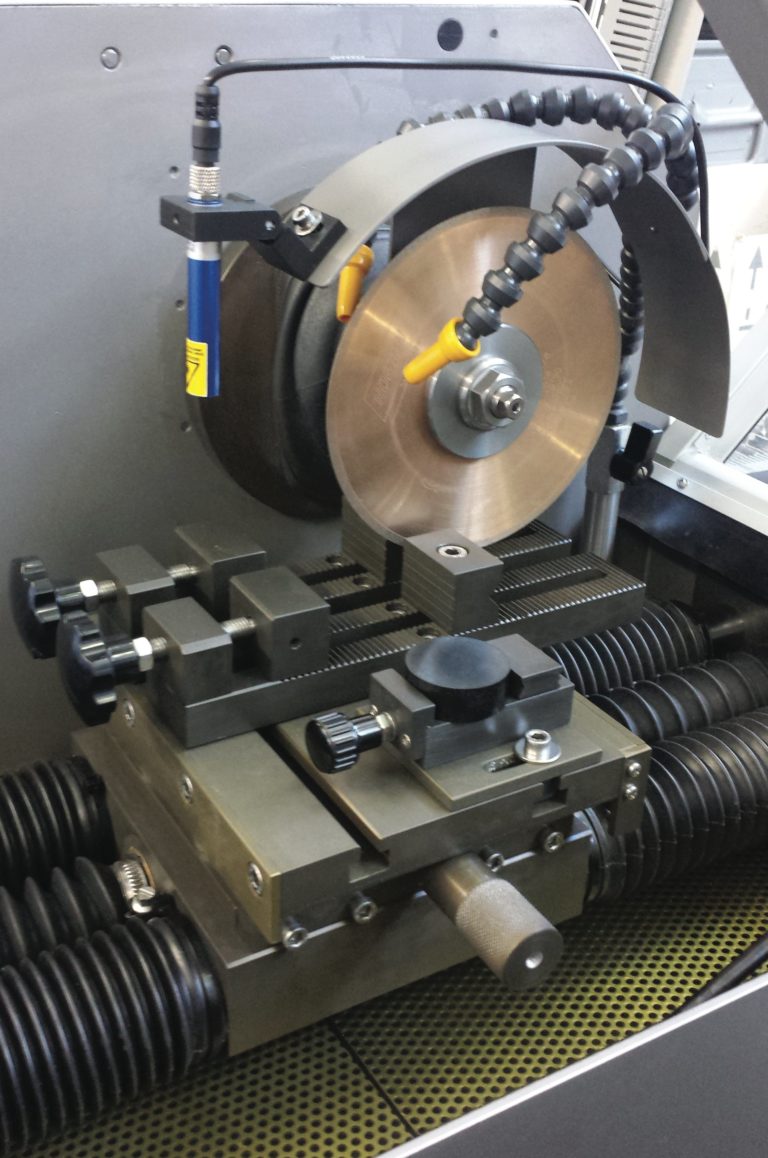

Cutting

The workpiece is cut as gently as possible using a cut-off machine with as much lubrication as possible so that the sample does not become deformed or overheated.

The aim is not to make the sample unrepresentative of its true microstructure.

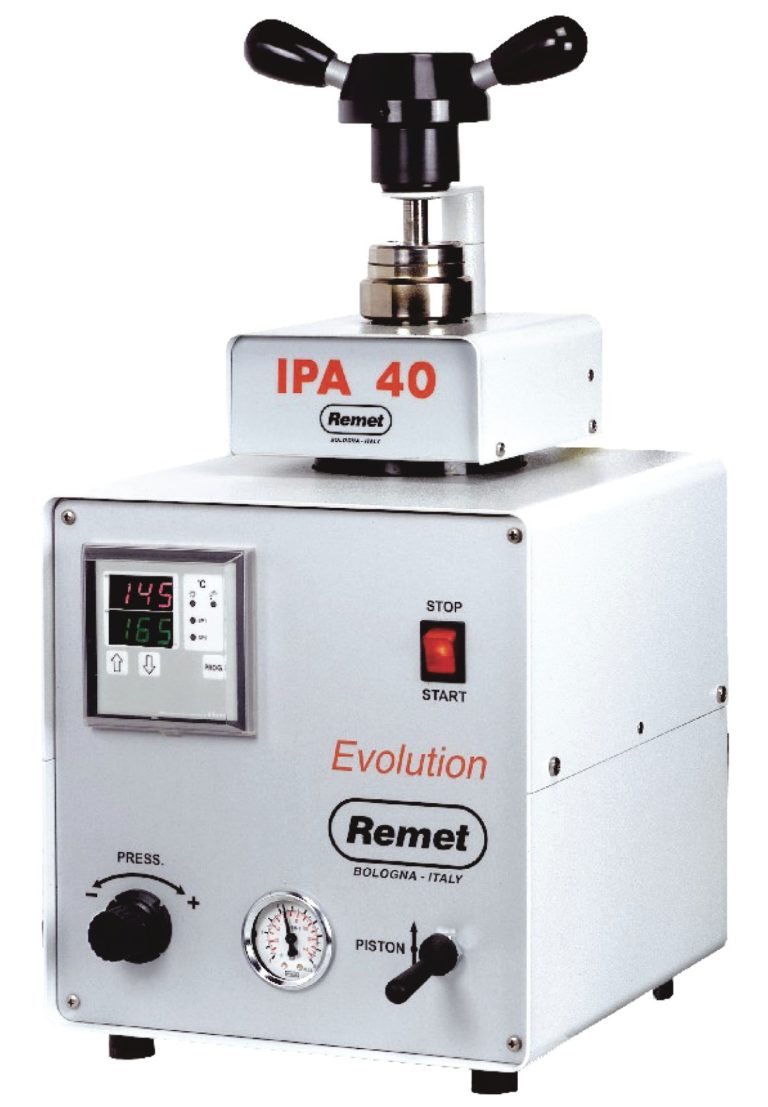

Coating

The sample is coated with resin to make it easier to handle, for example for small samples. It also protects fragile materials and ensures that the edges are perfectly sharp.

To ensure the best possible adhesion between the resin and the sample, it must be free from grease or other contaminants.

There are two types of mounting, hot mounting and cold mounting.

Hot mounting is suitable when you have a large series of samples to carry out. It also allows you to reduce process time while maintaining superior mounting quality. However, it is not suitable for temperature-sensitive samples. Hot mounting requires a mounting press combining pressure and high temperature.

Polishing

The aim is generally to observe details in the micrometre range, so polishing is necessary to ensure that the polishing scratches are as small as possible.