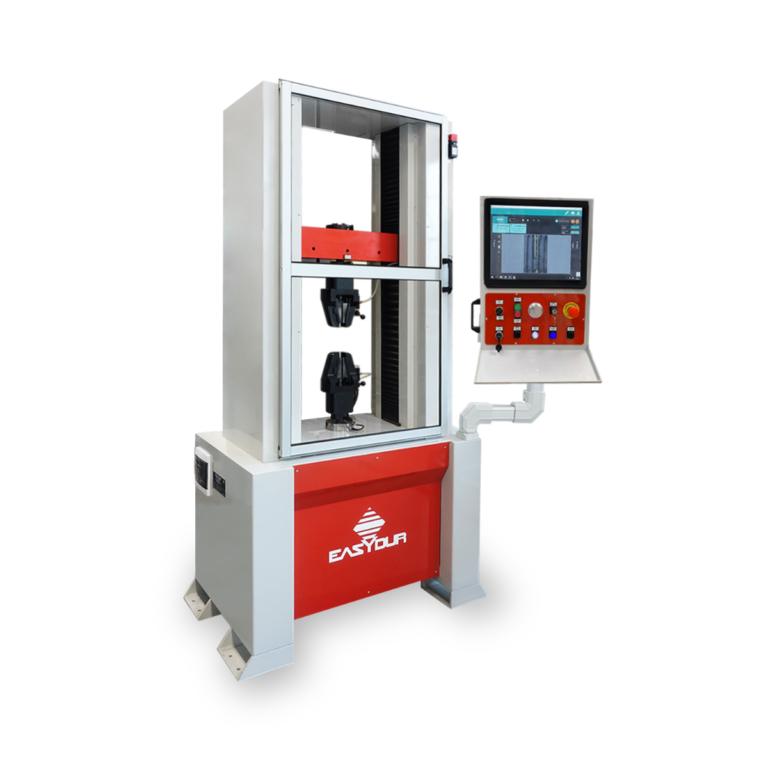

EASYDUR universal tensile and compression testing machines

The primary function of universal machines is to perform tensile tests. The purpose of this action is to characterise a specimen, whether prismatic or cylindrical, by applying a tensile force. The characterization is used to determine the size, strength, deformation at the break, and reliability of the material.

Universal testing machines are mainly used as laboratory machines in a wide range of industrial sectors, from aerospace to science and textiles. They are used to guarantee the quality and safety of finished products.

Resistance of materials (RM) is a branch of solid mechanics concerned with analysing the behaviour of materials subjected to loads or stresses. It studies the mechanical properties of materials and their ability to resist the external forces exerted on them.

MR aims to analyse the response of materials to these forces and determine their ability to withstand these loads without deforming or breaking. This analysis is essential for the design and construction of structures such as bridges, buildings, aircraft, ships, and vehicles.

MR uses concepts from physics and mathematics to study the behaviour of materials under different loads. The main concepts studied in MR include stress, strain, shear stress, bending, and torsion.

Stress is the force acting on a unit area of a material. Strain is the measure of the change in shape or size of material under the effect of force. Shear stress is the stress that occurs when a force is applied parallel to the surface of a material. Bending is the deformation that occurs when forces are applied perpendicular to a material, bending it. Torsion is the deformation that occurs when forces are applied in rotation around the axis of a material.

Using these concepts, MR can be used to determine the strength limits of materials as a function of their composition, structure, and shape. It can also be used to determine the material properties needed to ensure the safety and reliability of structures built using these materials.

In short, MR is a branch of solid mechanics that studies the mechanical properties of materials and their ability to resist external forces. It enables the strength limits of materials to be determined based on their composition, structure, and shape, which is essential for the design and construction of strong, reliable structures.

EASYDUR universal instruments can perform a variety of tests, making them versatile.

- A compression test is a device used to characterise the force of an object by compressing it.

- Flexure test: bending action

Suitable for a wide range of industrial needs, they can be used to test various forms of samples or materials (fabric, rubber, plastic, etc.).

Specific standards have been established for the materials to be tested :

- Plastic: ISO 527-1 and/or ISO 527-2 and/or ISO 175 and/or ASTM D638

- Composite: ISO 527-4 and/or ISO 527-5 and/or ASTM D3039

- Metal: ISO 6892-1 and/or ASTM370 and/or ASTM E8

- Fabric webs: ISO 13934-1, ISO 13937-2, ISO 1421

Depending on the machine model, there are different types of operation, which can be manual, semi-automatic, or automatic.

Test forces range from 10 N to 3000 KN (kilo Newton).

Easydur universal tensile testing machines for compression and tensile testing are designed and manufactured in Italy, north of Milan.

LEasydur is ACCREDIA-certified. Italian Accrédia = French Cofrac, international recognition between the various National Calibration Laboratories