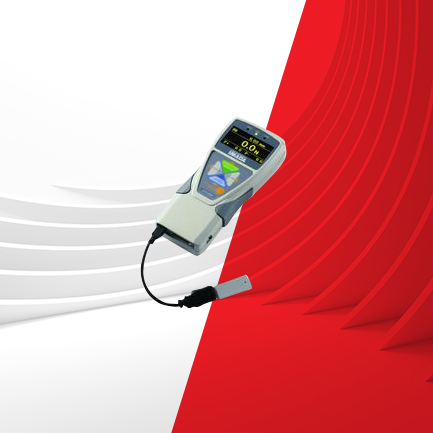

FORCE TRANSDUCERS

We offer force transducers with high tensile and/or compression capacities. This tool also has an integrated or separate display for forces from 200 grammes to 100 tonnes.

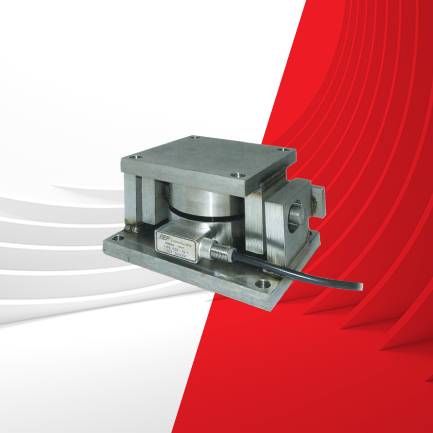

UPC weighing units are specially designed for C2S and CBS load cells from 100 kg to 100 tonnes.

Made from stainless steel, this floating assembly has been designed to facilitate the installation of weighing and dosing systems for tanks, reservoirs, and hoppers, whether static or subject to vibration.

The weighing unit is equipped with self-aligning load and transverse displacement compensation systems to ensure high-precision performance, even in the presence of eccentricities, thermal expansion, positioning errors, transverse thrusts, or structural deformations.