- PRODUCTS RANGE

- Special Hardness testing machine EASYDUR for metal industry and forges

- Food Control

- Manual measurement, hand tools

- Spring testing machine EASYDUR

- UTM, Universal testing Machine tensile & compression

- Weights & Balances – Mass measurement – Force measurement – Torque measurement

- Height gauge, height caliper and surface plate

- Coordinate Measuring Machine and Vision measuring system

- Microscope, Stereoscopic magnifier

- Roughness tester, Surface and profile measurement

- Hardness testing machine

- Metallography equipment, Metallography consumables

- Dynamometers and accessories

- Torquemeter and accessories

- Thickness measurement – Temperature measurement – Speed and time measurement

- High precision spirit levels, Electronic inclination measuring instruments

- Services

- CORPORATE

- Catalog and promotion

- Technical documentation

- User manuals

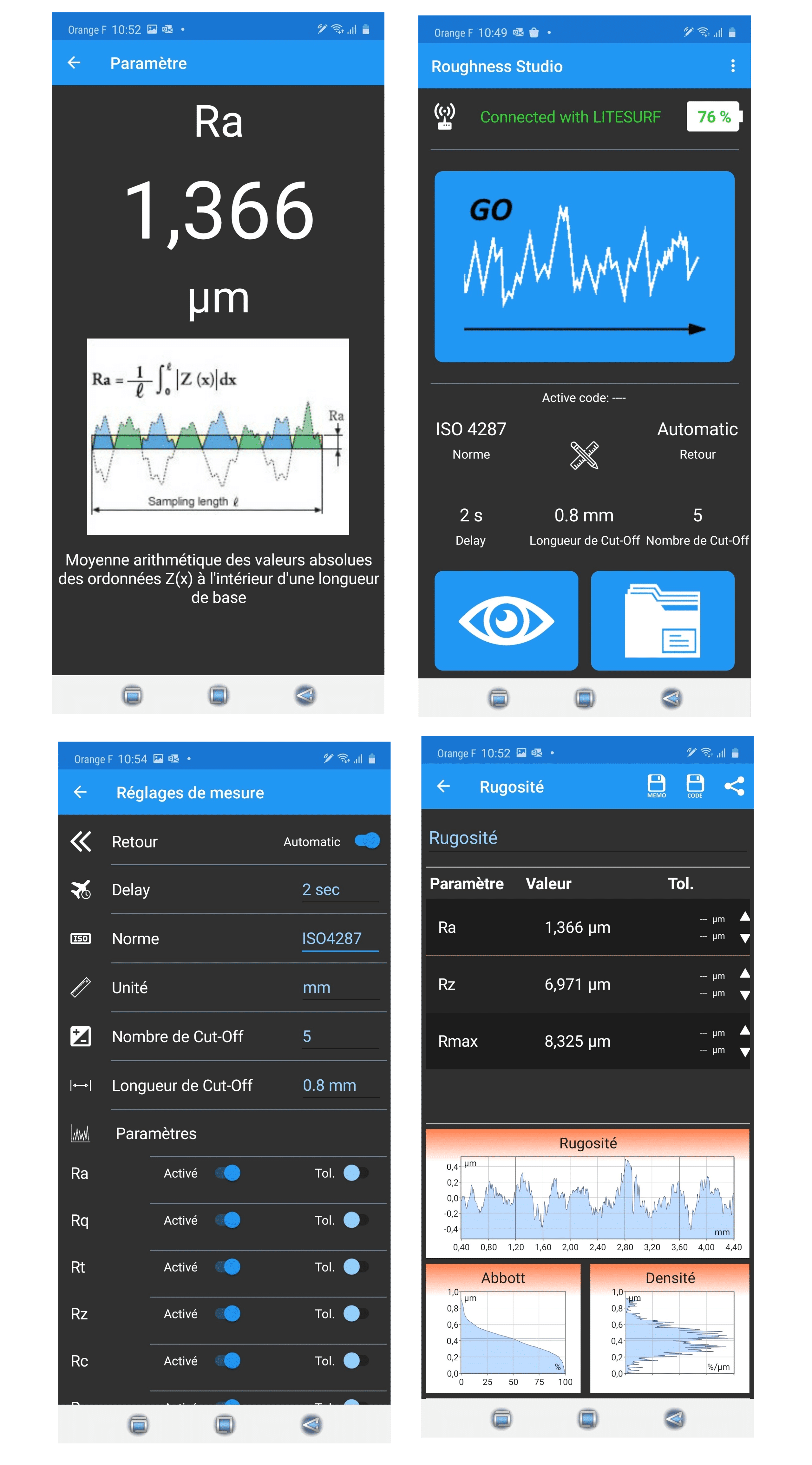

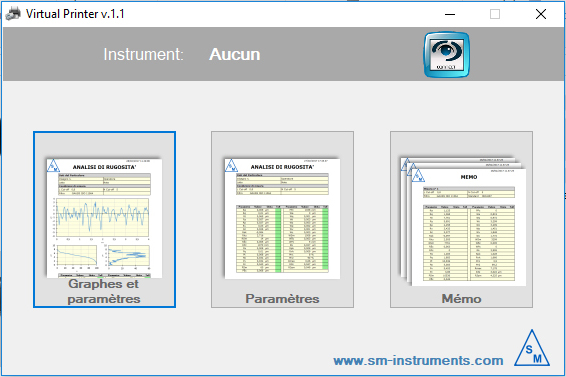

ROUGHNESS STUDIO Premium Surface Analysis Application

Promotion jusqu'au 31/07/2025 !

ROUGHNESS STUDIO Premium is the Android-compatible application, downloadable to tablets, smartphones and PCs, developed for the LiteSURF portable roughness tester:

The instrument and the app communicate via BLUETOOTH.

This latest-generation application enhances the performance of your instrument, enabling you to carry out a highly detailed analysis of the surface condition you want to monitor. Multilingual, it offers 44 roughness parameters and 4 calibration modes RA, Rz, Rsm and R (single pattern) as well as 6 CUT-OFF (0.025 – 0.08 – 0.25 – 0.80 – 2.5 – 8 mm).

It provides excellent traceability of your roughness measurement results.

|

LITESURF FEATURES |

|||

|

LiteSURF only |

With APP Basic (supplied as standard) |

With APP Premium |

|

|

Measuring Principle |

Differential Inductive – Probe With Shoe |

||

|

X Probe Travel |

17.5 mm |

||

|

Z Measurement Range |

250 µm (+50 µm, -200 µm) |

||

|

Résolution |

1 nm |

||

|

Cut-Off Length |

0,25 – 0,80 – 2,5 mm |

0,25 – 0,80 – 2,5 mm |

0.025 – 0.08 – 0,25 – 0,80 – 2,5 – 8mm |

|

Number of Cut-Off |

1-2-3-4- 5 |

1-2-3-4- 5 |

de 1 à 20 |

|

Filter |

Gauss |

Gaussian ISO 16610-21 (ex ISO 11562) |

Gaussian ISO 16610-21 (ex ISO 11562) ISO 13565-1 Gaussian robust ISO 16610-31

|

|

Speed |

0,5 – 1 mm/s |

0.5 – 1 mm/s |

0.5 – 1 mm/s |

|

Filtering of lS |

Second standard |

Secondestandard |

Second standard or déactivable |

|

Short Cut-Off |

NN |

NO |

YES |

|

Measuring Range |

1-2-4-8-12-16 |

1,5 – 2,5 – 4,5 – 6 – 8 – 12 -16 |

1,5 – 2,5 – 4,5 – 6 – 8 – 12 -16 |

|

Calibration |

Ra (ISO, unique) – R (MOTIF, unique) |

Ra (ISO, unique) – R (MOTIF, unique) |

Ra, Rz, Rsm (1 to 5 Bar Average) – R (REASON, Single) |

|

Memory |

Approximately 18,000 measurements with only roughness parameters

Approximately 30 measurements with profile (0.8×5) |

Unlimited (SmartPHONE internal memory) |

Unlimited (SmartPHONE internal memory) |

|

Language |

English, French, German, Italian |

English, French, German, Italian, Spanish, Portuguese, Chinese, Dutch, Swedish, Russian, Polish, Czech, Japanese, Korean, Romanian |

English, French, German, Italian, Spanish, Portuguese, Chinese, Dutch, Swedish, Russian, Polish, Czech, Japanese, Korean, Romanian |

|

Profile Charts |

NO |

Roughness, Pattern |

Primary, Roughness, Ripple, Abbott’s Broom, Lift, Pattern |

|

Paramètres |

8 Paramètres ISO 4287: Ra, Rq, Rt, Rz, Rc, Rmax, RSm, RPc,

MOTIF 12085: Pt, R, AR, Rx, Ppc

|

8 Paramètres ISO 4287: Ra, Rq, Rt, Rz, Rc, Rmax, RSm, RPc,

MOTIF 12085: Pt, R, AR, Rx, Ppc

|

44 Paramètres ISO 4287: Ra, Rq, Rt, Rz, Rp, Rv, Rc, Rsk, Rku, RSm, RΔq, RΔa, Rmax, Rδc, Rmr, RPc, RLo, Rlr, Rzjis, RHSC, R3z, hp, Ep JIS: Ra, Rq, Ry, RzJIS, tp, RSm, S

ASME: Rp, Rpm, RPc, Rsk, tp

MOTIF 12085: R, AR, Rx Rke, Rpke, Rvke, Mr1e, Mr2e, A1e, A2e

|

|

Interface |

128×64 Monochorme OLED |

||

|

Probe |

Interchangeable, swivel to 90° for lateral measurements |

||

|

Autonomy |

300 mesures (0,8 x 5) |

||

|

Dimensions, Weight |

160x34x33,5 mm, 200 g |

||