- PRODUCTS RANGE

- Special Hardness testing machine EASYDUR for metal industry and forges

- Food Control

- Manual measurement, hand tools

- Spring testing machine EASYDUR

- UTM, Universal testing Machine tensile & compression

- Weights & Balances – Mass measurement – Force measurement – Torque measurement

- Height gauge, height caliper and surface plate

- Coordinate Measuring Machine and Vision measuring system

- Microscope, Stereoscopic magnifier

- Roughness tester, Surface and profile measurement

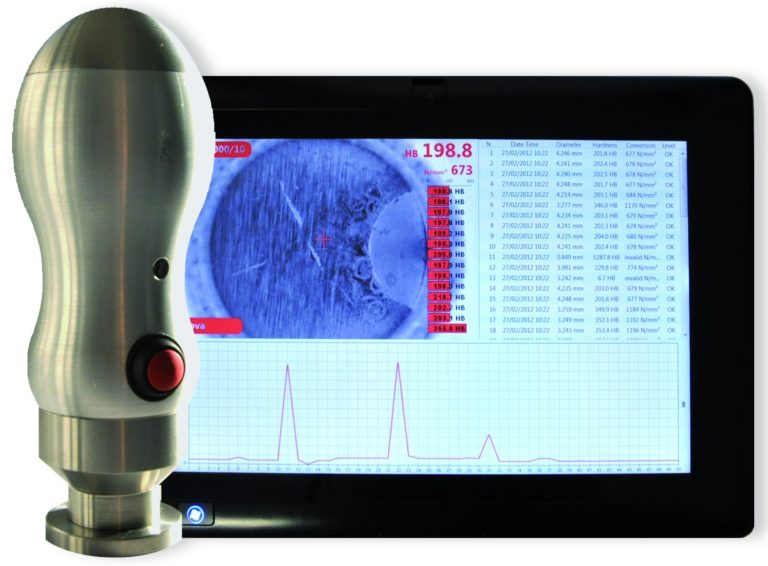

- Hardness testing machine

- Metallography equipment, Metallography consumables

- Dynamometers and accessories

- Torquemeter and accessories

- Thickness measurement – Temperature measurement – Speed and time measurement

- High precision spirit levels, Electronic inclination measuring instruments

- Services

- CORPORATE

- Catalog and promotion

- Technical documentation

- User manuals

Hardness Testing: Definition of the test and basic principles

Definition of a hardness test.

Hardness testing may seem abstract and difficult to some people.

Mastering the vocabulary and knowing how to read a hardness value demystifies the subject.

Before developing the different testing principles, ROCKWELL, BRINELL, VICKERS, SHORE and LEEB, it is important to know how to define a hardness test in order to understand and be understood by your interlocutor.

IMPORTANT CONCEPT: THERE IS NO RELATIONSHIP BETWEEN THE DIFFERENT HARDNESS SCALES.

50HRC ≠ 50HRB ≠ 50HV10

The hardness test is defined by 3 criteria, letters and numbers. The hardness value is always placed before the test criteria.

General hardness test :

Checking the hardness of materials, whether metallic or not, is not that simple. Several methods are used: Brinell, Rockwell, Vickers, Knoop, Shore (and a few others less commonly used). It’s a question of choosing the most suitable one to obtain the correct result.

As a general rule, the load should be chosen so that the depth of the indentation is less than one tenth of the thickness of the part or the layer of a surface treatment.

While respecting this rule, it is advisable to apply the highest possible load to the indenter.

The lower the load, the more polished the surface of the measured area should be.