- PRODUCTS RANGE

- Special Hardness testing machine EASYDUR for metal industry and forges

- Food Control

- Manual measurement, hand tools

- Spring testing machine EASYDUR

- UTM, Universal testing Machine tensile & compression

- Weights & Balances – Mass measurement – Force measurement – Torque measurement

- Height gauge, height caliper and surface plate

- Coordinate Measuring Machine and Vision measuring system

- Microscope, Stereoscopic magnifier

- Roughness tester, Surface and profile measurement

- Hardness testing machine

- Metallography equipment, Metallography consumables

- Dynamometers and accessories

- Torquemeter and accessories

- Thickness measurement – Temperature measurement – Speed and time measurement

- High precision spirit levels, Electronic inclination measuring instruments

- Services

- CORPORATE

- Catalog and promotion

- Technical documentation

- User manuals

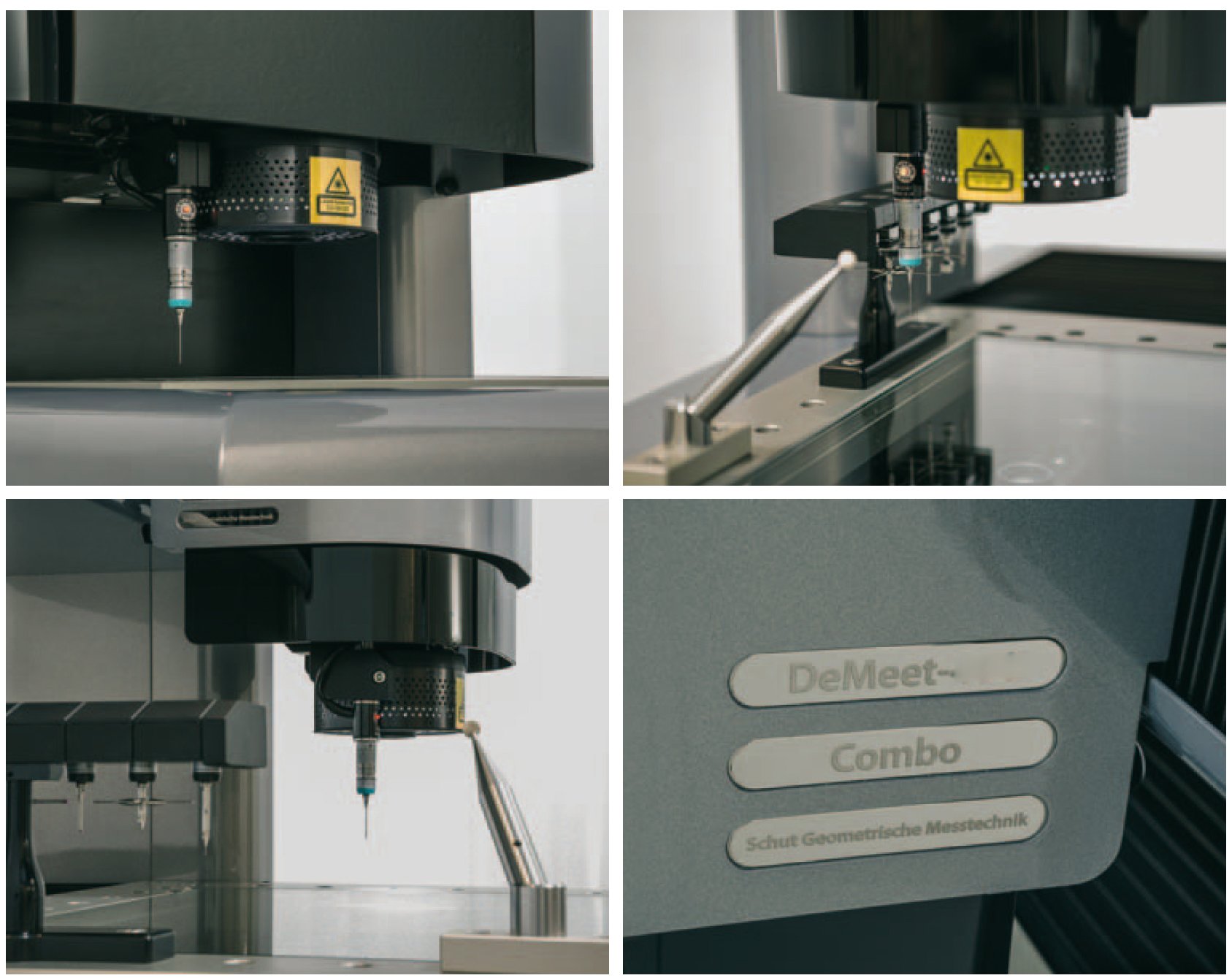

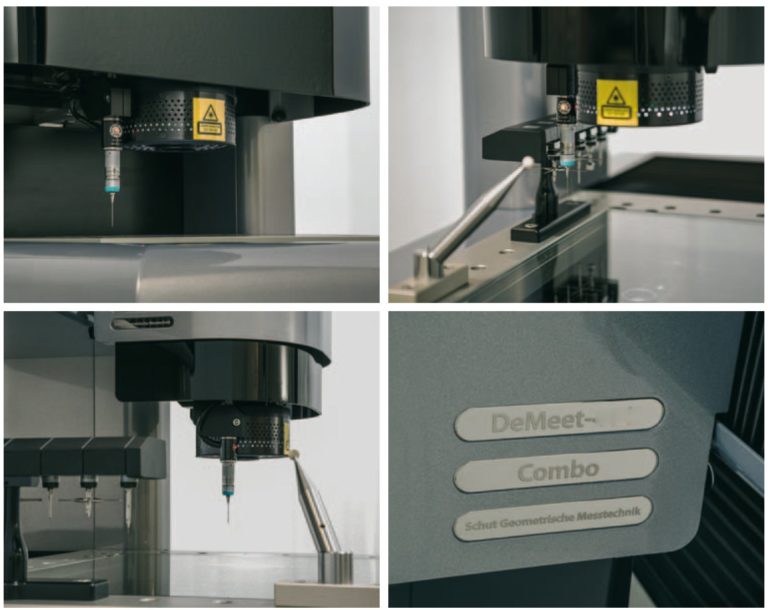

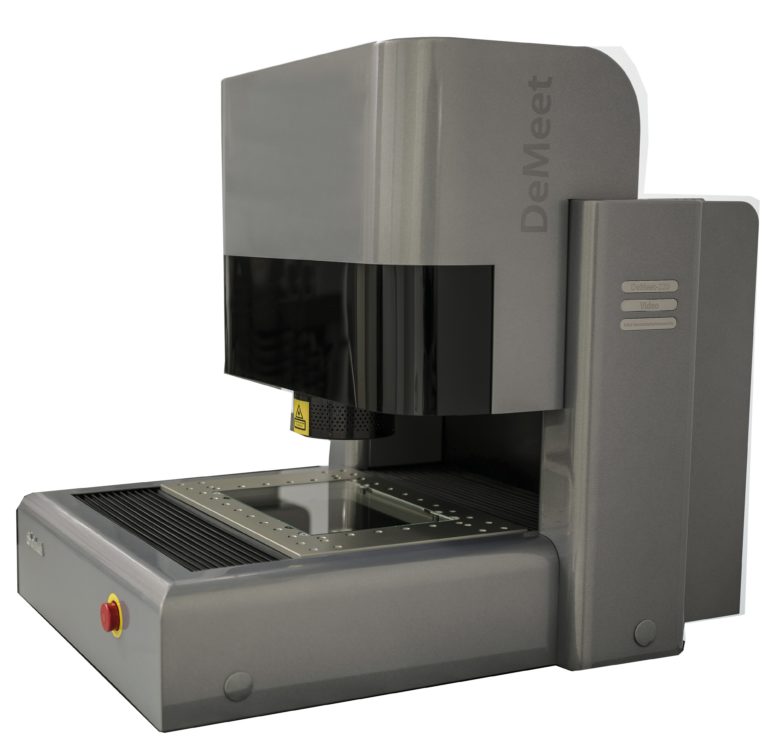

Coordinate Measuring Machine, 3D VIDEO And PALPAGE Measuring System – DeMeet COMBO 400

The DeMeet 400 series 3D CNC measuring machine:

- Multi-sensor technology: video and probing

- When measuring certain parameters, the limits of non-contact measurement are encountered. DeMeet measuring machines can be additionally equipped with a probe system.

With the DeMeet Combo model, the two principles are integrated and measurements can be made using both the optical system and the probe system. - As standard, the machines are equipped with a Renishaw TP20 5-channel stylus configuration.

- Applications for multi-sensor technology can be found in the precision mechanics, medical, plastics and electronics sectors.

- The 3D Approve for DeMeet AfDM multisensor software is easy to use and ensures fast, straightforward operation.

- It offers a logical and intuitive interface. For single or series measurements, the software assists you in controlling your production process: inspection, programming, measurement, reporting and control.

- The measurement program is displayed in a tree structure for creation and editing. It is possible to use video measurements and probing measurements within the same program.

- Imaging is based on scanning technology, with automatic edge detection using sophisticated algorithms. Noise and dust in the image are filtered out.

- Very fast 3D controls and smooth, rounded movements are achieved thanks to improved motor control. The image is transformed simultaneously with the movement of the machine.The results can be easily reported in PDF format or exported to software such as Approve DeMeet DataManager for statistical analysis.

DeMeet 400 Series CNC 3D MEASURING MACHINE, COORDINATE MEASURING SYSTEM:

- Measuring capacity (mm) X=400, Y=250, Z=200

- Load capacity (kg) 50

- Dimensions (mm) 835x880xHt1590

- Weight (kg) 510