- PRODUCTS RANGE

- Special Hardness testing machine EASYDUR for metal industry and forges

- Food Control

- Manual measurement, hand tools

- Spring testing machine EASYDUR

- UTM, Universal testing Machine tensile & compression

- Weights & Balances – Mass measurement – Force measurement – Torque measurement

- Height gauge, height caliper and surface plate

- Coordinate Measuring Machine and Vision measuring system

- Microscope, Stereoscopic magnifier

- Roughness tester, Surface and profile measurement

- Hardness testing machine

- Metallography equipment, Metallography consumables

- Dynamometers and accessories

- Torquemeter and accessories

- Thickness measurement – Temperature measurement – Speed and time measurement

- High precision spirit levels, Electronic inclination measuring instruments

- Services

- CORPORATE

- Catalog and promotion

- Technical documentation

- User manuals

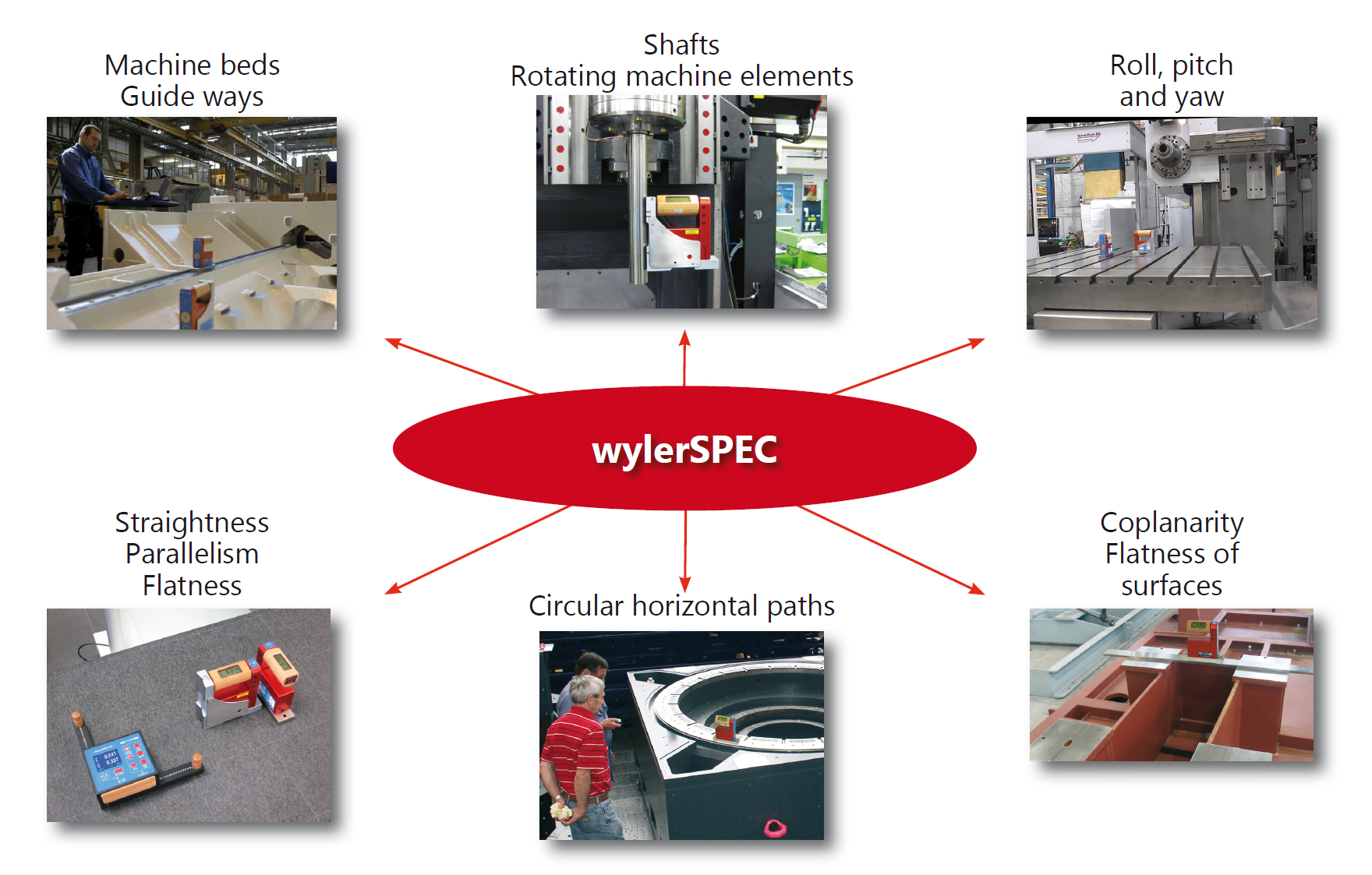

WylerSPEC_WylerELEMENTS, Software For Machine Tool Geometry Control & Marble Mapping

What does checking the geometry of a machine involve?

- This operation consists of checking the integrity of the machine’s structure to guarantee its performance and precision.

The main operations involved in checking a machine are as follows:

- pitch and roll

- Yaw

- Perpendicularity

- Spindle rotation

- Flatness

With the WylerSPEC software you will have the ideal tool to control your machine tools in static and dynamic, to measure tasks related to the geometry of objects and machines such as straightness of guides, flatness of surfaces, granite tables and machine tables, parallelism of guides horizontal parts. WylerSPEC integrates the two packages WylerELEMENTS and WylerPROFESSIONAL. While WylerELEMENTS covers basic applications such as straightness and flatness, WylerPROFESSIONAL is suitable for more complex applications such as measuring guides or circular supports on machines.

The main features of the wylerSPEC software are :

- User-friendly

- Direct interpretation of results

- Adaptability to your measurement tasks

- Modular design

- Efficient – time can be saved by measuring multiple variances simultaneously

- Integration of laser interferometers and autocollimators

WylerSPEC software replaces WYLER LEVELSOFT PRO and MT-SOFT. Its user-friendliness and informative display of readings make it even easier to set up, calibrate and measure machines. Universal: WylerSPEC allows measurement readings to be taken not only from WYLER tilt measuring instruments, but also from laser interferometers and autocollimators, making it easy to carry out geometry checks on machine tools and marble mapping.